Direct materials quantity variance

The difference between actual quantity of materials used to manufacture a certain number of units and the quantity allowed by standards to manufacture that number of units multiplied by standard direct materials rate is called direct materials quantity variance or direct materials efficiency variance. In other words, when actual quantity of materials used deviates from the standard quantity of materials allowed to manufacture a certain number of units, materials quantity variance occurs.

Favorable or unfavorable variance

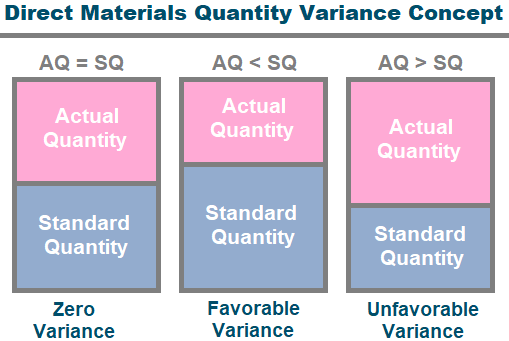

Like direct materials price variance, this variance may be favorable or unfavorable. If workers manufacture a certain number of units using a quantity of materials that is less than the quantity allowed by standards for that number of units, the variance is known as favorable direct materials quantity variance. On the other hand, if workers use the quantity that is more than the quantity allowed by standards, the variance is known as unfavorable direct materials quantity variance.

The materials quantity variance may be computed either in quantity or in dollar amount. Suppose, for example, the standard quantity to manufacture an executive table is 5 feet of teak wood but the table is manufactured by actually using 5.50 feet of wood, the variance in quantity would be 0.50 feet – unfavorable. If the teak wood costs $6.00 a foot, the variance in dollars would be $3.00 (= 0.50 feet × $6.00). For proper financial measurement, the variance is normally expressed in dollars rather than quantity.

Formula

This variance may be computed using the following formula:

Direct materials quantity variance = (Actual quantity used × Standard rate) – (Standard quantity allowed × Standard rate)

Or

= Standard rate x (Actual quantity used – Standard quantity allowed)

Example 1

Premium Furniture, a US based Inc., uses a standard costing system to control its direct materials and conversion costs. During the month of December 2022, its workers used 3,750 feet of timber to finish 1,500 office chairs. The standard length of timber allowed to manufacture an office chair is 2.75 feet and the standard rate per foot of timber is $3.50. How much is the direct materials quantity variance of Prime Furniture Inc. for the month of December 2022? Also mention whether it is favorable or unfavorable.

Solution

= (3,750 feet × $3.50) – ( 4,125 feet* × $3.40)

= $13,125 – $14,025

= $900 favorable

or

= $3.40 × (3,750 feet – 4,125 feet* )

= $13,125 – $14,025

= $900 favorable

*Standard quantity of timber allowed to manufacture 1,500 chairs:

= 1,500 units × 2.75 feet

= 4,125 hours

In this case, Prime Furniture Inc. has experienced a favorable direct materials quantity variance because its workers finished 1,500 chairs by using only 3,750 feet of timber which is less than the total length of timber allowed by standards (4,125 feet) for this production.

Example 2

Angro Limited, a single product American company, employs a proper standard costing system. The normal wastage and inefficiencies are taken into account while setting direct materials price and quantity standards. Variances are calculated and reported at regular intervals to ensure the quick remedial actions against any unfavorable occurrence.

The standard price of materials purchased by Angro is $2.00 per kg and standard quantity of materials allowed to produce a unit of product is 1.5kg. During December 2020, 5,000 units were produced using 8,000kgs of direct materials. Calculate direct materials quantity variance and also indicate whether it is favorable or unfavorable.

Solution

= ( 8,000kgs × $2.00 ) – ( 7,500kgs* × $2.00)

= $16,000 – $15,000

= $1,000 Unfavorable

Or

= $2.00 × (8,000kg – 7,500kg*)

= $2.00 × 500kg

= $1,000 Unfavorable

*Standard materials allowed to manufacture 5,000 units:

= 5,000 units × 1.5kg

= 7,500kg

In this question, Angro has experienced an unfavorable direct materials quantity variance because the actual usage of materials (i.e., 8,000kgs) is more than the standard quantity allowed (i.e., 7,500 kgs) to manufacture 5,000 units pf product.

Causes of unfavorable direct materials quantity variance

An unfavorable direct materials quantity variance means excessive use of direct materials which may be the result of one or more of the following reasons:

- Inexperienced or untrained workers

- Lack of motivation

- Lack of proper supervision

- Use of outdated machinery

- Faulty equipment installed in factory

- Purchase of unsuitable or substandard materials

- Wastage and evaporation due to improper or inefficient handling of materials in factory

- Frequent power failures (wastage may occur due to unscheduled stop and start of machinery and equipment used in manufacturing process)

- Relying on incomplete or inaccurate data while setting direct materials quantity standards

- Theft of materials and negligence in recording the quantity issued to factory

Responsibility of the variance

Generally, the production managers are considered responsible for direct materials quantity variance because they are the persons responsible for keeping a check on excessive usage of production inputs. However, purchase managers may purchase low quality, substandard or otherwise unfit materials with an intention to improve direct materials price variance. In such cases, the responsibility of any unfavorable quantity variance would lie on the purchasing department. Irrespective of who appears to be responsible at first glance, the variance should be brought to the attention of concerned managers for quick and timely remedial actions.

The direct materials quantity variance should be investigated and used in a way that does not spoil the motivation of workers and supervisors at work place. Variances occur in most of the manufacturing processes and for almost all cost elements. The ultimate motive behind their calculation is to control costs and enhance improvement. They should not be used as tools to find someone to blame or degrade.

Leave a comment