Measuring and recording direct materials cost

After accepting a job or order, the first step in a job order costing system is to determine the direct materials requirement to complete the job. The type and quantity of direct materials required to manufacture a product can be determined either by using a bill of materials or by production staff.

Bill of materials is a document that lists the type and quantity of direct materials required to manufacture a standard product. But companies using job order costing system frequently receive orders that require customization in design, size and color etc. In such circumstances, the bill of materials cannot be used to determine the type and quantity of materials required to complete the job. Therefore the production department determines materials requirement using the information provided by customers.

After direct materials requirement has been determined, the production process starts with issuance of direct materials. For this purpose, production department prepares a document known as ‘materials requisition form‘. An authorized person from production department writes the type, quantity, and job number (to which the materials cost is to be charged) on materials requisition form. A signed copy of this form is then sent to the storeroom clerk who completes the form by entering on it per unit and total cost of materials to be issued. After necessary verification, storeroom clerk issues direct materials to production department.

A complete materials requisition form is also used by accounting department to record direct materials cost on the job cost sheet of the related job order.

An example/sample of materials requisition form is given below:

Use of computer technology for materials requisition:

The procedure described above is the manual procedure of issuing materials. In today’s business world, many companies are replacing manual procedure with computer technology. In computer technology, automated information processing systems are used to send the requisition information to storeroom. The material is transferred from storeroom to the production department on the basis of this information. An entry about each requisition is made in a computer that automatically updates the subsidiary materials record.

Journal entries to record the flow of materials:

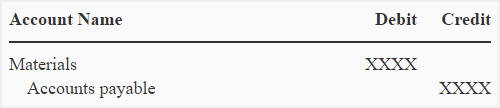

Normally two types of journal entries are made for direct materials cost. One at the time of purchase of direct materials from suppliers and one at the time of issuance of direct materials from storeroom to production department. These two entries are given below:

When materials are purchased:

When materials are issued:

Leave a comment